Tips for Industrial Aluminum Profiles Maintenance

Industrial aluminum profiles require maintenance during their usage process so that they can be used longer. So what are the tips? We have compiled the following eleven aspects:

Industrial aluminum profiles require maintenance during their usage process so that they can be used longer. So what are the tips? We have compiled the following eleven aspects:

Aluminum profiles are generally used in the construction industry. Industrial profiles and construction profiles are both grade 6063 aluminum alloy, and their composition and content are the same. Although their mechanical properties are not much different, their differences in performance are obvious. Next, I will introduce the differences between industrial aluminum profiles and construction aluminum profiles:

The difference between aluminum profiles and aluminum alloys is that in life, we may often see aluminum profiles, such as aluminum doors and windows, aluminum plates, curtain walls, etc., and many mechanical accessories, all contain aluminum profiles. Aluminum profiles are made by hot-melt extrusion of aluminum rods to obtain different shapes.

Industrial aluminum profiles are widely used in various industries for their unmatched strength, durability, and versatility. However, to ensure optimal performance and enhance their aesthetic appeal, proper surface treatment and finishes are crucial. In this blog, we will explore the importance of surface treatment and discuss the different finishes available for industrial aluminum profiles, with a focus on the renowned brand, Otalum.

Aluminum profile frame: The application range of aluminum profile products in the field of industrial framework is relatively wide, such as equipment frame, electrical bracket, industrial hanger, scientific research platform, etc., All they can be realized through aluminum profile processing and assembly.

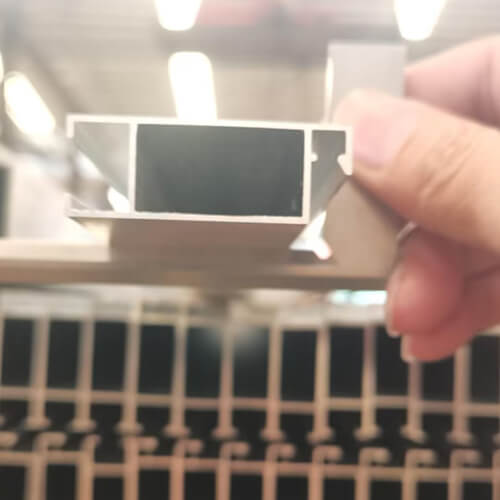

Aluminum extrusion profiles are aluminum components formed by forcing heated aluminum rods through specially designed molds to create various shapes and cross-sections. This extrusion process enables the manufacturing of aluminum alloys in a variety of complex geometric shapes, including angle aluminum, G-shapes, U-shapes, H-shapes, T-shapes, tubing, cylinders, and more.