- Our factory covers an area of 60000 square meters, and has more than 300 workers.

- We have 20 sets of extrusion lines, 2 sets of anodizing line, 2 sets of powder coating line and 2 sets of transfer wood grain lines

Our factory owns complete production lines from aluminum log casting to the aluminum profiles deep processing:

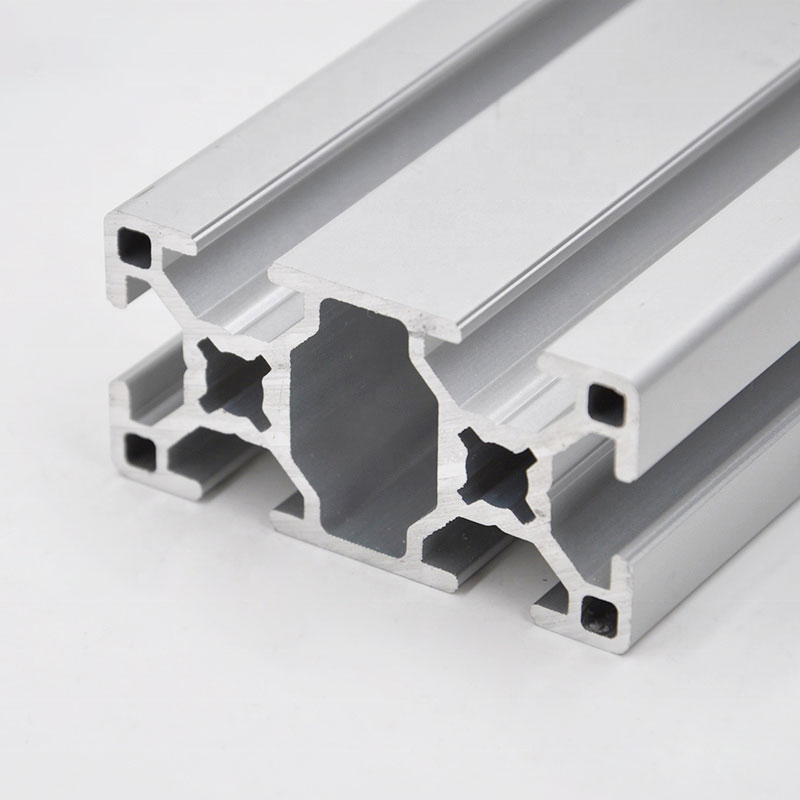

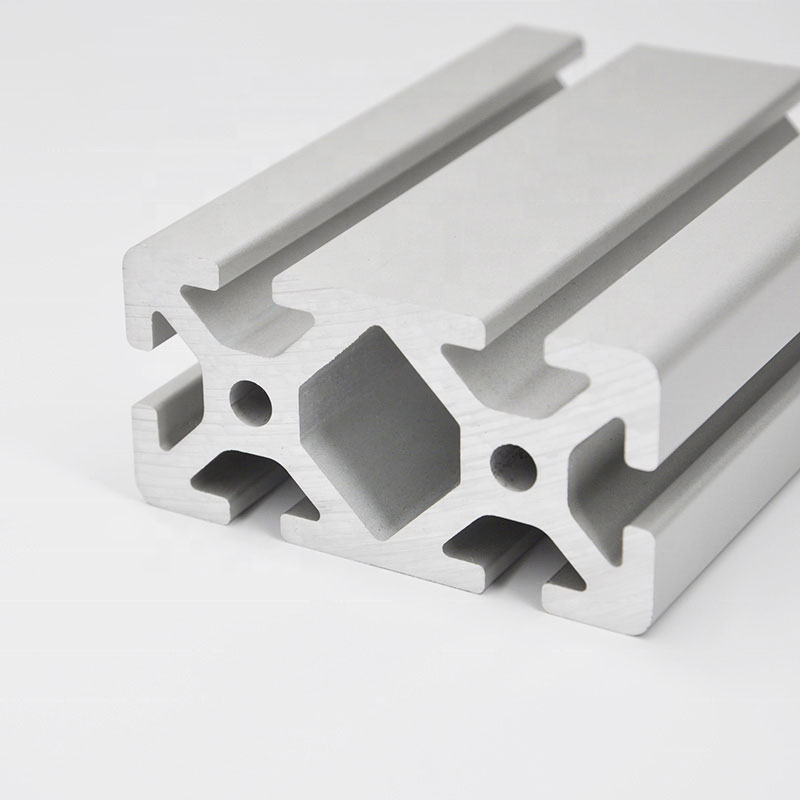

1. Our extrusion process produces high quality mill finish aluminum profiles, the extrusion dies are carefully maintained so they enhance the smoothness of the profile surface.

2. Pre-treatment method of sand-blasting, mechanical polishing, brushing would be done before anodizing and powder coating, it offers more stylish choices like bright or matt surfaces for the raw extruded profiles, and the most important thing is to terminate the extrusion lines, remove the surface dirt and oil stains.

3. Post-treatment method of of anodizing, powder coating, wood grain, electrophoresis would give aluminum profiles more color choices and better weather resistance.

We offer many kinds of surface treatments to our customers, and the aluminum profiles will be more resistant to chemicals, moisture, ultraviolet light, or some extreme weather conditions. It will also reduce the risk of chipping, corrosion, scratches, peeling or fade.

Our aluminum profiles may be used for all types of windows and doors in residential, commercial and industrial building construction.

Q1: Can I visit your factory?

A: YES, welcome to visit us, our factory is located in non-ferrous industrial base, qingchen district, qingyuan city, guangdong, China. We would be pleased to pick you up from Baiyun airport or Guangzhou Nan high-speed train station or your hotel address in Guangzhou.

Q2: How to ensure the quality of aluminium profile I purchased?

A: We have professional inspection team to check the quality, starting from mill finish profiles extrusion, our QC will pick out any potential inferior profiles with mechanical lines, then for anodizing or powder coating etc. When the order is finished and ready for shipping, testing report will be done by QA for PASS.

Q3: How long it takes to finish the order?

A: Our production capability per month over 2000 tons, it takes about 20 days to get ready for a 40HQ container ready. But for the first new order, as the new moulds are needed to be created and tested normal, would last a month or so.

Q4: What is the payment terms?

A: Usually we prefer T/T deposit and balance payment against B/L copy, and L/C is also very common.